O.M.P. Srl is a company that mainly deals with precision mechanical machining on behalf of third parties and it is aimed at large industrial groups operating in the various sectors listed below:

Founded in 1976, it has its production site in Puglia and covers an area of approx. 12,300 m2 of which 5,800 are covered.

O.M.P. S.r.l. has worked since the dawn of time in direct contact with large industrial groups. This relationship carried out in synergy with customers, has triggered a process of professional growth of human resources. The company's workforce varies, at present, between 65 and 75 units. In this scenario, the market and customers of a national and non-national industrial type have led the company management to demand ever greater competence standards from its staff and the entire structure, both in technical and organizational fields. The skills of the technicians and labourers, the commitment and intelligence belonging to the continuity of their work has enabled the company, which every day expresses its deepest gratitude, to progress in the field of precision mechanics to place it today among the most qualified companies in the sector. This demonstrates that, behind the apparent coldness of technology and the most advanced achievements of mechanics, there is always the intellectual commitment and sensitivity of a human being. Among the critical processes, welding is required to play a role of considerable importance: there are, for this process, resources and qualified procedures according to the European standards UNI EN 9606, EN ISO 15614-1 and ASME IX (SMAW-SAW- GMAW-GTAW-FCAW) for carbon steels and stainless steels also for cryogenic applications. For non-destructive testing methods, the company relies on its internal staff for VT, LP and UT tests and on qualified service providers with personnel certification according to UNI EN ISO 9712, as well as UNI CEI EN ISO 17025 accredited laboratories.

We fulfill do our duty as a matter of principle, for ourselves, for our dignity.

High-tech industrial machines, for the development of a perfect product in every field.

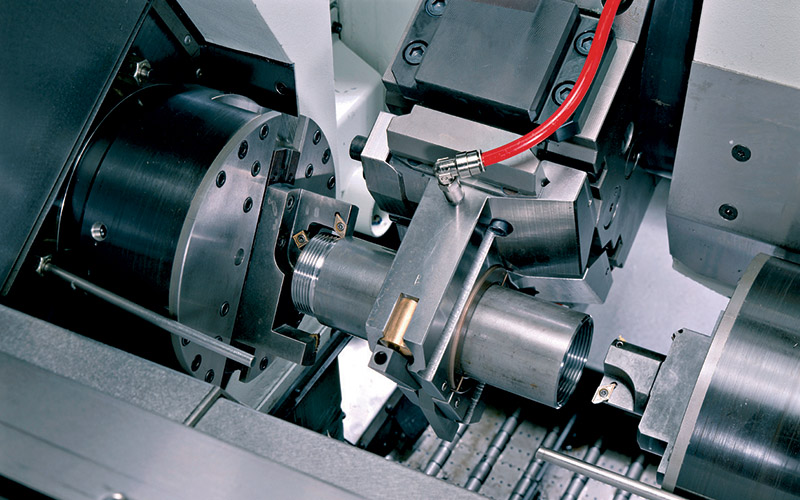

We produce mechanical components that require a high level of precision.

The seriousness of our work is the key that makes the customer appreciate us.

A machine can do the work of fifty ordinary men, but no machine can do the work of an extraordinary man.

The production process is organized by order with the help of management tools. The main activities that are performed for the fulfillment of a job are the following:

Some processes are outsourced:

The production phases carried out in house are the following:

The production plants are mainly made up of multipallet machining centers, vertical and parallel lathes with numerical control.

Welding machines for GTAW, GMAW, SMAW, SAW processes.

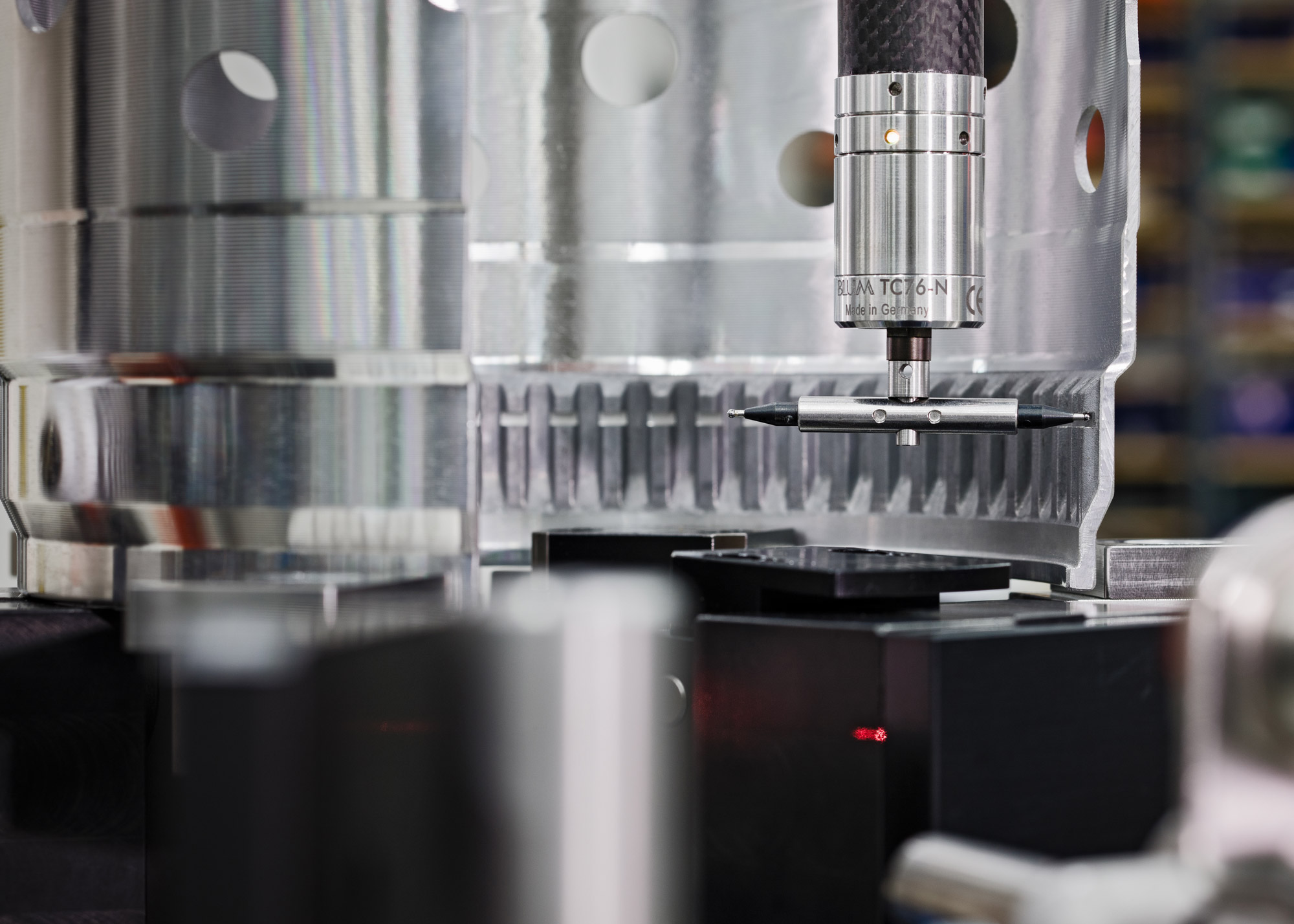

The heart of the company consists of the metrology room, where highly specialized personnel carry out the production control and testing phases.

The metrology room is also equipped with three-dimensional control machines (DEA, COORD3) and a 3D portable touch probes and laser control system. (Hexagon System absolute arm mod 8545-7 axis with scanner RS6)

Some typical operations are flanges, shafts, bridge boxes for transmissions, oil pans, manifolds, balls, shells, bodies and drives for valves and pumps, rotors for gas turbines, cross heads for reciprocating compressors, complete hydraulic distributors, welded columns for cryogenic use bodies and covers of large butterfly valves, carpentry, as well as production of specific equipment (clamping or assembly tools for large productions, pallets) of the customer.

Carlone Maria Michela

michela.carlone@ompsrl.com

Tel. +39 0883 382228

Purchasing Office

Fabio Carlone

fabio.carlone@ompsrl.com

Tel. +39 0883 382224

Responsible for the Finance and Banks

Carlone Michela

michela.carlone@ompsrl.com

Tel. +39 0883 382228

Administration and Human Resource Manager

Sassi Giovanni

giovanni.sassi@ompsrl.com

Tel. +39 0883 382231

Customers’ Accounts

Carlone Michela

michela.carlone@ompsrl.com

Tel. +39 0883 382228

RSPP

Lettini Pasquale

pasquale.lettini@ompsrl.com

Tel. +39 0883 382223

Cannone Sebastiano

sebastiano.cannone@ompsrl.com

Tel. +39 0883 382232

Warehouse Manager

D'Ambra Antonio

antonio.dambra@ompsrl.com

Tel. +39 0883 382242

Production Director

Cannone Sebastiano

sebastiano.cannone@ompsrl.com

Tel. +39 0883 382232

Outsourcing Suppliers Office

Cannone Mariantonietta

cannonemariantonietta@ompsrl.com

Tel. +39 0883 382249

Production Planning

Carlone Fabio

fabio.carlone@ompsrl.com

Tel. +39 0883 382224

D'Ambra Antonio

antonio.dambra@ompsrl.com

Tel. +39 0883 382242

Commercial Director

Carlone Fabio

fabio.carlone@ompsrl.com

Tel. +39 0883 382224

Technical Direction

Tricarico Savino

savino.tricarico@ompsrl.com

Tel. +39 0883 382225

Welding Coordinator

Mauro Gaetano

gaetano.mauro@ompsrl.com

Tel. +39 0883 382222

Responsible Quality

Mauro Gaetano

gaetano.mauro@ompsrl.com

Tel. +39 0883 382222

Management Responsible Testing

Melacarne Alessandro

alessandro.melacarne@ompsrl.com

Tel. +39 0883 382234

Switchboard: +39 0883 693023 - +39 0883 693649 - +39 0883 694161

Administration: +39 0883 693304

Workshop: +39 0883.382245 - +39 0883 382236

Resident Supervision: +39 0883 382240

Prima Traversa Mingone, 1

Minervino Murge (BT)

76013 - Italia

P. IVA 00779930726

Tel: +39 0883 693023

Tel: +39 0883 693649

Tel: +39 0883 694161

Fax: +39 0883 693304

Do you need help? Any questions? Send us a message and we will call you!